RESEARCHES

Smart Vision & Robotic Sensing

Professor, Robotics Laboratory

Smart Innovation Program, Graduate School of Advanced Science and Engineering

Hiroshima University

Smart Innovation Program, Graduate School of Advanced Science and Engineering

Hiroshima University

Idaku ISHII

- >> Research Contents

- In order to establish high-speed robot senses that are much faster than human senses, we are conducting research and development of information systems and devices that can achieve real-time image processing at 1000 frames/s or greater. As well as integrated algorithms to accelerate sensor information processing, we are also studying new sensing methodologies based on vibration and flow dynamics; they are too fast for humans to sense.

High-Speed Glossy Surface Scanner

In this study, we develop our high-speed glossy surface

scanner, which estimates surface reflectance properties for

conveying objects.

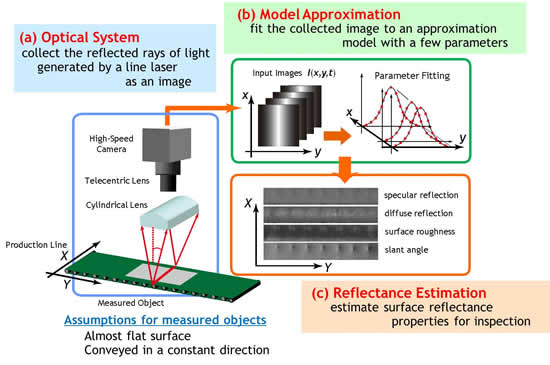

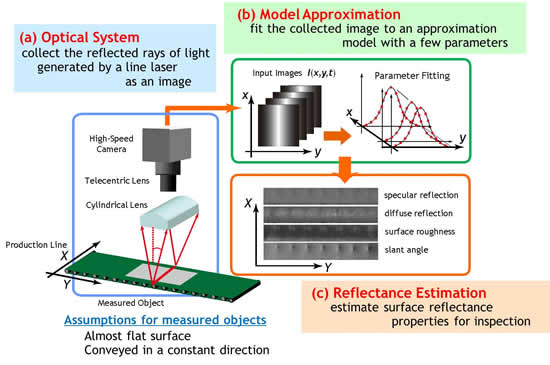

Our concept consists of three phases: (a) the optical system,

which collects the reflected rays of light generated by a line

laser into an imager as an image; (b) the model approximation,

which fits the collected image to an approximation model

with a few parameters; and (c) the reflectance estimation,

which estimates surface reflectance properties for inspection.

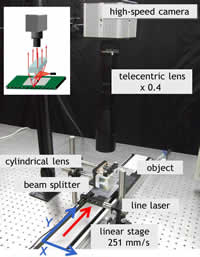

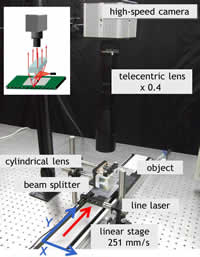

Using the glossy surface scanner, a single image,

which was condensed with reflected rays of light in different

directions using a cylindrical lens, is processed on a high-speed

vision platform. Surface reflectance properties estimated at 1000

fps were realized in real time for 1024×1024 pixel images by hardware-implementing a circuit module for obtaining parameters of surface reflectance properties on an FPGA of the H3 Vision.

Using the glossy surface scanner, a single image,

which was condensed with reflected rays of light in different

directions using a cylindrical lens, is processed on a high-speed

vision platform. Surface reflectance properties estimated at 1000

fps were realized in real time for 1024×1024 pixel images by hardware-implementing a circuit module for obtaining parameters of surface reflectance properties on an FPGA of the H3 Vision.

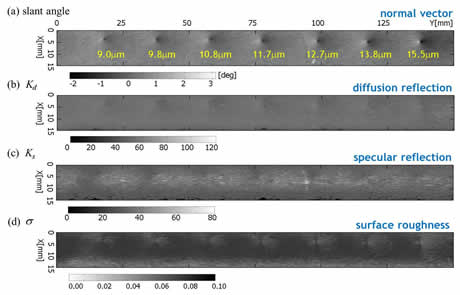

We verified the accuracy of the high-speed glossy surface scanner by measuring the surface reflectance properties of a flat, pressed metal plate with defects. On the pressed metal plate, there were 7 dents at 20mm intervals; their heights were 9.0, 9.8, 10.8, 11.7, 12.7, 13.8, and 15.5um, respectively. In this study, a 15mm×150mm area of the pressed metal plate was inspected in 0.7s. The glossy surface scanner could simultaneously detect small defects that were too small to be seen with the naked eye.

We verified the accuracy of the high-speed glossy surface scanner by measuring the surface reflectance properties of a flat, pressed metal plate with defects. On the pressed metal plate, there were 7 dents at 20mm intervals; their heights were 9.0, 9.8, 10.8, 11.7, 12.7, 13.8, and 15.5um, respectively. In this study, a 15mm×150mm area of the pressed metal plate was inspected in 0.7s. The glossy surface scanner could simultaneously detect small defects that were too small to be seen with the naked eye.

metal plate inspection MP4 movie(3.6M) |

|