RESEARCHES

Smart Vision & Robotic Sensing

Professor, Robotics Laboratory

Smart Innovation Program, Graduate School of Advanced Science and Engineering

Hiroshima University

Smart Innovation Program, Graduate School of Advanced Science and Engineering

Hiroshima University

Idaku ISHII

- >> Research Contents

- In order to establish high-speed robot senses that are much faster than human senses, we are conducting research and development of information systems and devices that can achieve real-time image processing at 1000 frames/s or greater. As well as integrated algorithms to accelerate sensor information processing, we are also studying new sensing methodologies based on vibration and flow dynamics; they are too fast for humans to sense.

Intelligent HFR Video Logging for Machinery Surveillance

This study introduces a form of vision-based machinery surveillance for abnormal behavior detection in high-speed periodic operation. To allow periodic machinery operations to be monitored, the surveillance algorithm can estimate the phase of a periodic operation by inspecting temporal changes in the brightness at several significant pixels in an input image from a single camera; abnormal behavior in periodic operation can be intelligently detected at a crucial moment.

We propose a real-time periodic phase extraction algorithm, including of BDT(Binary-Decision_Tree), Phase Encoding and Phase Renumbering. First, series of HFR images of normal high-speed motion should be prestored. Second, we design the BDT algorithm to select the significant pixels by subdividing the prestored time stamps. Third, from the selected pixels, we extract the periodic tentative phase by using algorithm of Phase Encoding. Next, the tentative phase can be renumbered and unified as standard periodic phase.

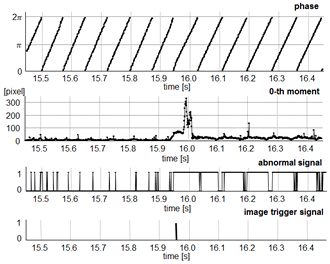

In online processing, we should calculate the M-dimensional brightness vector by using the selected pixels for each input image. The correspondence phase can be searched from reference phase data according to brightness vector. Meanwhile, the matched reference image and reference mask image will be selected from the reference data. The system can judge and count the abnormal pixels by matching an input image with reference images. When the abnormal behavior is happening, the system can detect it and generate the trigger signal for HFR video recording.

We used a camera head and IDP Express for HFR-video-based machinery surveillance, including real-time abnormal behavior detection and HFR video recording.

The algorithm is software executed on the PC at 1000fps for 8-bit gray-level images of 128×128 pixels, which are taken from input images of 512×512 pixels with an interval of 4 pixels. When the abnormal behavior is detected, the system will record the HFR video of 512×512 pixels .

The algorithm is software executed on the PC at 1000fps for 8-bit gray-level images of 128×128 pixels, which are taken from input images of 512×512 pixels with an interval of 4 pixels. When the abnormal behavior is detected, the system will record the HFR video of 512×512 pixels . We detected abnormal behavior in a periodic operation and recorded an HFR video during a crucial period while the needle of the sewing machine was vertically operated at 12.5Hz. In the experiment, the needle of the sewing machine was suddenly dislocated after it was significantly deformed and its broken fragment flew rapidly from the camera’s view.

|

sewing machine MPG(8.9M) |

|

HFR movie AVI(4.3M) |

Reference

- Yao-Dong Wang, Idaku Ishii, and Takeshi Takaki : HFR-Video-Based Machinery Surveillance for High-Speed Periodic Operations, Journal of System Design and Dynamics, Vol.5, No.6, pp.1310-1325 (2011)

- Yao-Dong Wang, Idaku Ishii, Takeshi Takaki, and Kenji Tajima : An Intelligent High-Frame-Rate Video Logging System for Abnormal Behavior Analysis, Journal of Robotics and Mechatronics, Vol.23, No.1, pp.53-65 (2011)

- Idaku Ishii, Yang-Dong Wang, and Takeshi Takaki : Visual Machinery Surveillance for High-Speed Periodic Operations, Proc. IEEE Int. Conf. on Intelligent Robots and Systems, pp.1208-1213, 2011.